Passenger Alert: Nigeria is About to Record Another Air Disaster

On Wednesday June 14, 2023, an Aero Contractors Boeing 737-500 with the tail identifier 5N-BLE took off from Nnamdi Azikiwe International Airport, Abuja shortly after dark on a scheduled service to Sokoto with over 100 passengers onboard. It never made it to Sokoto. Within a few minutes of takeoff, the pilot declared an undisclosed emergency and returned to Abuja. Three weeks later on Friday July 7, 2023, a Max Air Boeing 737-3H4 with the tail identifier 5N-MHM took off from the same airport at about 12:15 with nearly 100 passengers onboard. This flight actually made it to Yola Airport and the passengers disembarked safely.

What both sets of passengers did not know was that they had narrowly escaped becoming the victims of Nigeria’s largest civil air disaster since Dana Air Flight 0992 in June 2012. The passengers on the Sokoto-bound flight were never told exactly what happened, neither were the disembarking passengers on the Abuja-Yola flight informed that they had just survived what could easily have been their last-ever journey. In fact, it is only after reading this story that these passengers will realise just how close they came to death in a Jet-A1 fireball somewhere in the Sahel.

Here is what happened.

Max Air And The Fuel Sump That Never Happened

Like many other regional airlines in Nigeria and around the world, Max Air favours the Boeing 737 aircraft family. For airlines that offer short and middle distance hops connecting tiny cities like Yola with major hubs like Abuja, the 737 is the 2004 Toyota Corolla of the sky – an extremely popular, sturdy, reliable, low-drama aircraft that does what it says on the tin and does not require too much maintenance.

Despite its low-maintenance reputation, even the 737 cannot mitigate for deliberate failure to adhere to operating procedures or refusal to follow the standard pre-flight checklist. This checklist ensures that the pilot or engineer spots any visible damage to the fuselage or flight surfaces, and that fuel and hydraulic systems are confirmed to be functioning properly before lifting 40 tons of metal and kerosene 6KM into the sky.

One of the most important items on this checklist is the daily fuel sump. To “sump” the fuel in an aircraft’s fuel tanks means to drain any water that has found its way into the tanks and settled to the bottom, since water is heavier than jet fuel. For the reasons listed below, it is extremely important to make sure that water is not allowed to remain inside an aircraft’s fuel tank.

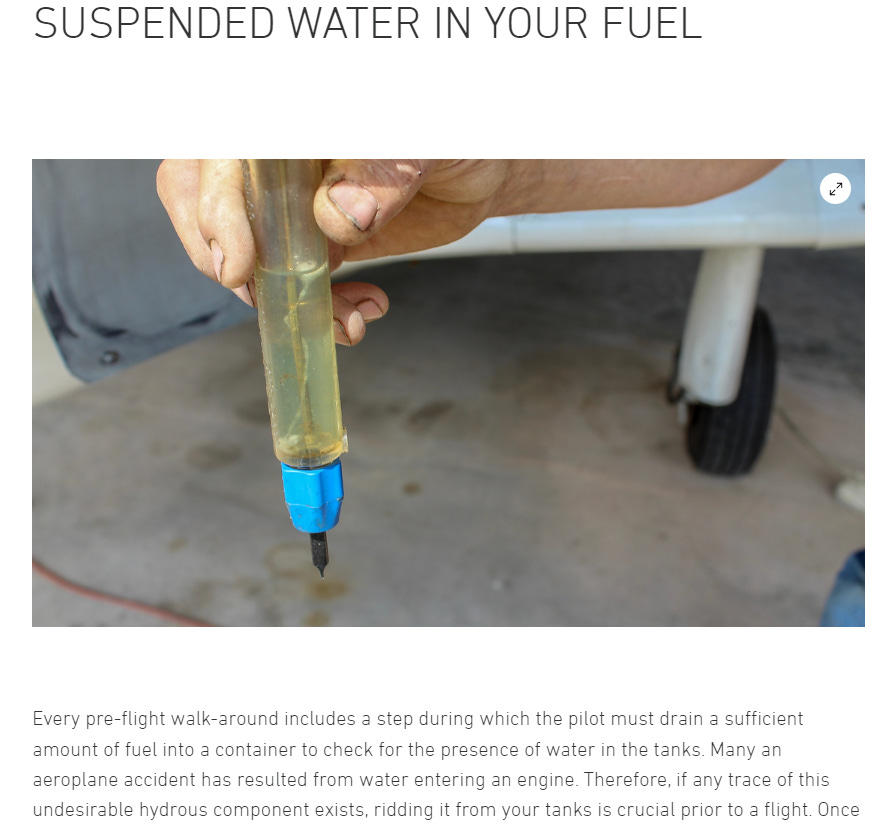

When the Max Air flight took off from Abuja on July 7, the passengers might have imagined that this and other parts of the pre-flight checklist were carried out. The video you will see below indicates otherwise. According to the whistleblower who is an airline insider, as soon as the plane landed in Yola, the pilots immediately demanded a water check on its fuel tanks. Recalling his reaction he said,

“I wondered what they detected during flight that made them immediately carry out a water check on the fuel tanks.”

His question was answered immediately when the fuel was sumped on the tarmac in Yola and this happened:

According to this whistleblower, “multiple drums of water” were collected from both tanks of the aircraft which had just landed. [For perspective, one drum is about 208 litres.]

I spoke to an industry expert who asked to remain anonymous and asked her how such an amount of water could even come to be inside an aircraft’s fuel tank to begin with. This was her response:

“The suppliers of Jet-A1 keep the fuel in underground storage tanks before transferring it to a road tanker that will convey it to the airport. From there, the airlines buy it and have it supplied to their aircraft. During the rainy season, the likelihood of having water in the fuel increases. The NCAA requires these fuel suppliers to carry out what we call a “water check” using special strips that change colour when in contact with water. Before fueling the aircraft in Abuja, they should have carried out this check by sampling a small amount of fuel from the bottom of the tank, since water settles at the bottom unlike jet fuel. If this check is not carried out, it becomes a problem.

“Of course, water could enter the tank from the aircraft itself due to condensation that happens due to temperature variation at different altitudes. But the quantity of water that will find its way into the tank this way is usually very small. That is why part of the pre-flight inspections that the pilots or engineers must carry out includes sumping the water that may have settled at the bottom of the tank. This clearly was not done here, and it could have had tragic consequences including loss of engine thrust mid-flight.”

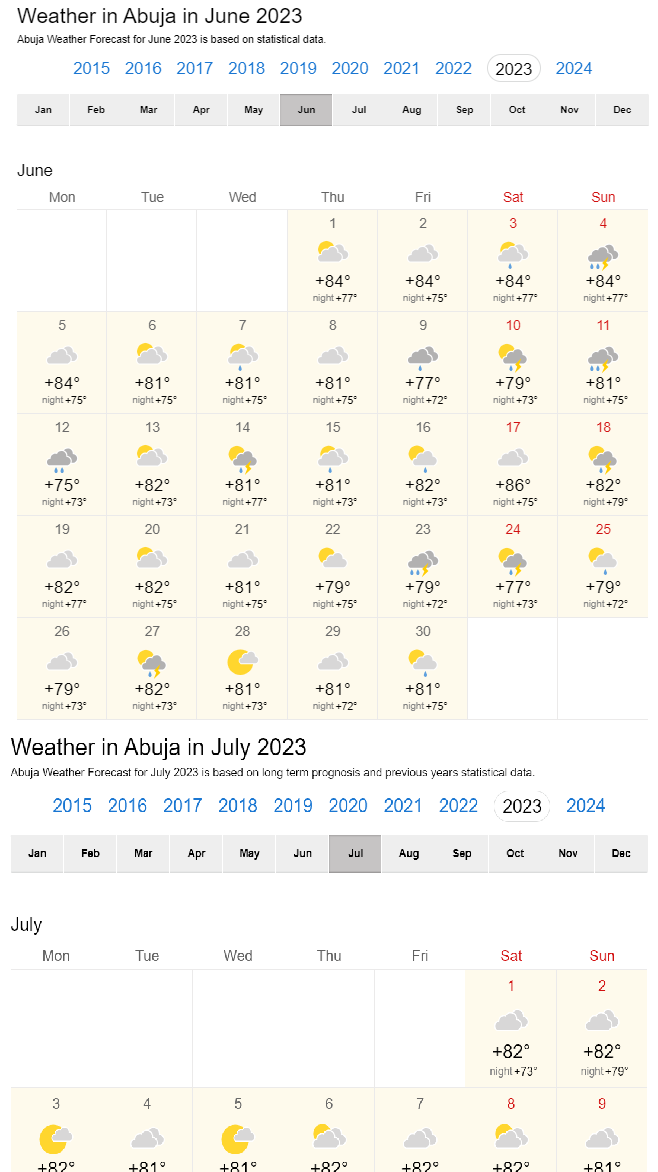

A glance at the weather records for Abuja over that period confirms that in the 30 days preceding July 7, Abuja experienced significant rainfall at least 14 times. If there were ever a time for rainwater to get into the underground jet fuel storage tanks from where this aircraft would be supplied, that would be it. This would align with the expert’s hypothesis for how so much water somehow got into the fuel tank of a fully loaded commercial passenger aircraft.

What it does not explain is why despite the existence of daily procedures and pre-flight checklists specifically designed to make sure that a 40-ton civilian airliner does not risk an engine flameout at 28,000 feet due to water in its fuel tank turning into ice pellets, Max Air’s 737 somehow flew the 568KM distance from Abuja to Yola with a mid-sized GeePee tank’s worth of water inside its fuel tank – risking nearly 100 lives in the process.

Even more disturbingly, after having apparently failed to follow the mandatory pre-flight checklist, the pilots apparently noticed something in-flight that made them rightly suspect that there was water in the plane’s tanks. What did they notice? Loss of engine thrust? Perhaps a full or partial engine flameout? We will probably never know because following Max Air’s most recent safety incident before this one – a crash landing involving another 737 in Abuja on May 7, 2023 – the Nigerian Safety Investigation Bureau discovered that the airline still overwrites its cockpit voice recorder data in contravention of NCAA rules.

Aero Contractors And The Broken Stabiliser

Like the passengers who would head to Yola 3 weeks later, Mustapha’s friend was also travelling from Abuja on a Boeing 737. 5N-BLE, which belonged to the embattled airline Aero Contractors, was ferrying over 100 passengers from Abuja to Sokoto when the emergency situation mentioned in the tweet above forced the pilot to abort the journey and return to Abuja immediately. That flight to Sokoto eventually never happened – in fact Aero Contractors has not flown at all since June 14, 2023.

The reason for this, as exclusively revealed to me by an insider at the airline is that 5N-BLE was in fact, the airline’s only serviceable aircraft. In violation of NCAA regulations which do not permit an airline with only one aircraft to obtain an Air Operator Certificate, Aero Contractors had been winging it for weeks, placing severe burden on its sole useable fixed-wing commercial aircraft. What eventually grounded 5N-BLE and the rest of the AMCON-owned airline with it however, was much worse than the “engine trouble” imagined by the passengers on that flight.

Below is a video exclusively obtained from a whistleblower with knowledge of the matter. In the video, shortly after the pilot declared an emergency and returned to Abuja, engineers conducting a walk-around examination of the aircraft discovered that the horizontal stabiliser panel and elevator panel on its tail section were both broken, rendering the aircraft nearly impossible to control and completely unsafe to fly.

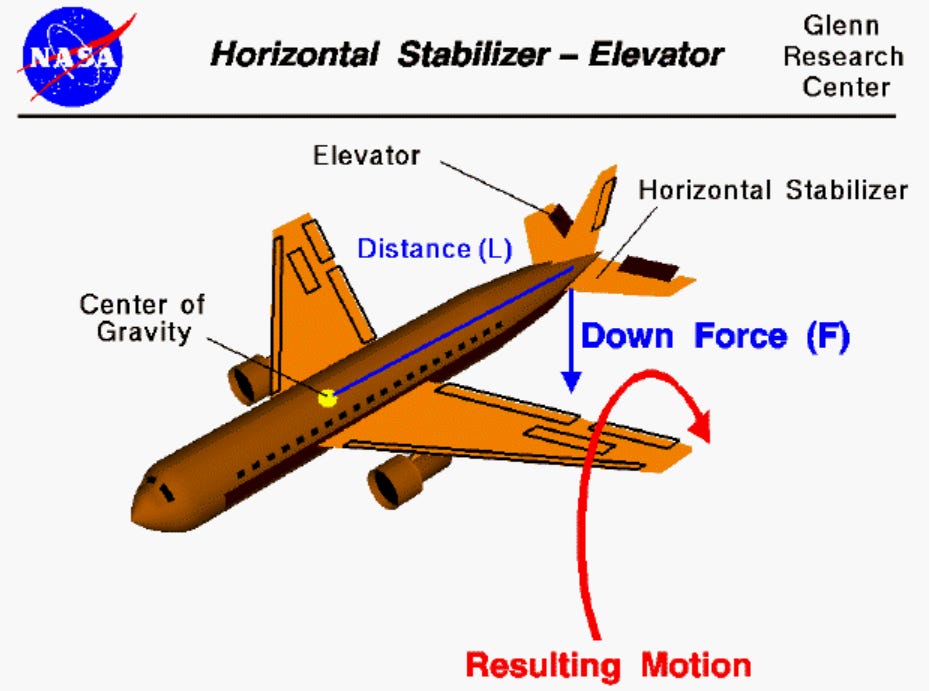

To put what you have just seen into its true context, it is important to explain what a horizontal stabiliser is and how it works. In layman’s terms, an aircraft’s horizontal stabiliser, vertical stabiliser and elevator are the flight surfaces that keep it level and under the pilot’s control. Without functioning stabilisers, pilots cannot control an aircraft’s nose or altitude, neither can they counteract the sideways roll tendency of what is essentially a heavier-than-air aluminium tube moving through the thin upper atmosphere at 650km/hr.

Without functioning engines, a plane may be able to glide to a safe landing. Without functioning stabilisers however, a Boeing 737 becomes little more than a 41-ton piece of falling Papier-mâché – completely uncontrollable and inevitably destined to slam into the ground. To understand what happens to a passenger aircraft without functioning stabilisers, you can refer to the tragic story of Japan Air Lines Flight 123.

Fortunately in this case, before the stabiliser failed altogether and sent 100 passengers onboard to certain death in a kerosene fireball, the pilot managed to carry out an emergency landing at Nnamdi Azikiwe International Airport. My source informed me that the passengers who would almost certainly have died, were not told what happened, and still have no idea how close they came to perishing that night. I suppose they know now.

For reference, it is a standard requirement on every pre-flight checklist for the pilot to conduct a walkaround inspection. This checklist item is intended specifically to ensure that there are no cracks or visible damage.

If this checklist item had been carried out, it is almost impossible that signs of the stress and damage would not have been noticed before attempting to ferry 100 people 678KM across the Sahel. Had the pilot noticed the aircraft’s control problems much later in the flight, this could easily have been Nigeria’s first major civil aviation disaster since 2012. The clear and obvious implication here is that just as with the Max Air Abuja-Yola flight, the pre-flight checklist was – yet again – not followed by a pilot working for a Nigerian airline.

Passengers Confirm Air Peace May 26 Incident

In West Africa Weekly Aviation Special [Part 1], I reported the testimony of a whistleblower who witnessed a serious unreported aviation accident at Akanu Ibiam International Airport, Enugu on Friday May 26. The incident, which involved an Air Peace ERJ-145LR with the tail identifier 5N-BXF has now been corroborated by a passenger on the flight who reached out, and a relative of a flight crew member who spoke about the incident on a Twitter Space I hosted. Below are their stories.

About The Author

4 Comments

Leave a Reply Cancel reply

Related Articles

Exclusive: MI6, CIA-linked NGOs, Bill Gates Are Directly Writing Nigeria’s Security, Health, Food And Tax Laws

Foreign intelligence agencies and foreign organisations – including those tied to the...

ByMayowa DurosinmiJuly 11, 2025EXPOSED: US Embassy in Uganda Runs Clandestine Foreign Interference Program Targeting East African Journalists

The United States Embassy in Kampala, Uganda is actively involved in Foreign...

ByWest Africa WeeklyMay 26, 2025Biyi Toluwalase Puts Story First in Every Nollywood Film He Edits

The editor behind Gangs of Lagos, Sista, and Makemation talks about invisible...

ByIkenna ChurchillMay 16, 2025‘Technical Glitch’: Nigeria’s Institutions and Their Habit of Avoiding Accountability

In Nigeria, “technical glitch” has become a catch-all excuse to deflect blame...

ByWest Africa WeeklyMay 14, 2025

Raiden Roy

Vida Peck

Maisie Marin